15 Plywood Storage Ideas to Organize Your Workshop

Transform your cluttered workshop with these 15 practical plywood storage solutions that maximize space and boost productivity efficiently.

Have you ever walked into your workshop only to find yourself stepping over scattered plywood sheets like they're oversized playing cards? You're not alone in this struggle. Managing plywood storage can feel like trying to solve a Rubik's cube blindfolded, but it doesn't have to be that way. Proper plywood organization isn't just about tidiness; it's about protecting your investment, maximizing your workspace, and ensuring safety in your creative haven. When you store plywood correctly, you prevent warping, reduce damage, and save precious time searching for the right piece. Think of your workshop as a kitchen where every ingredient needs its designated spot. Just as a chef needs easy access to spices and utensils, you need your materials within arm's reach and in perfect condition.

1. Vertical Wall-Mounted Rack System

Installing a vertical wall-mounted rack transforms unused wall space into a plywood storage powerhouse that keeps sheets upright and accessible. This system uses sturdy brackets attached directly to wall studs, creating compartments that separate different plywood thicknesses and types. You'll protect your investment from moisture damage since sheets stay elevated off the floor while maintaining their flat profile. The beauty of this approach lies in its simplicity and cost-effectiveness, requiring only basic materials like two-by-fours and heavy-duty screws. Position your rack near your cutting area to minimize carrying distance and reduce physical strain. Consider adding labels to each section for quick identification of material grades and dimensions. This storage method works exceptionally well in workshops with limited floor space but generous wall real estate. Your plywood remains visible at a glance, eliminating the frustrating search through stacked sheets.

2. Rolling Plywood Cart for Mobility

A rolling plywood cart brings unprecedented flexibility to your workshop by allowing you to move materials exactly where you need them during projects. This mobile solution features heavy-duty casters that glide smoothly across concrete or wooden floors, with locking mechanisms ensuring stability during loading and unloading. The frame typically consists of welded steel or sturdy wood construction with angled supports that prevent sheets from sliding out. You can position dividers to create separate compartments for various plywood sizes, from quarter-inch panels to three-quarter-inch sheets. The portability factor becomes invaluable when you're working on large projects that require frequent material access or when you need to reconfigure your workspace layout. Many woodworkers discover that mobility reduces physical strain and improves workflow efficiency significantly. Your cart becomes a traveling workstation that follows you around the shop rather than forcing you to make repeated trips.

3. Overhead Ceiling Storage Solution

Utilizing ceiling space for plywood storage frees up valuable floor and wall areas while keeping materials safely out of your primary work zone. This overhead system requires careful installation into ceiling joists using lag bolts and steel brackets capable of supporting substantial weight. You'll need to consider ceiling height carefully since accessing stored materials requires a stable ladder or rolling platform. The method works brilliantly for storing full sheets you don't access frequently, such as specialty woods or future project materials. Installing pulleys or a simple hoist mechanism can make retrieval safer and more efficient for heavier plywood grades. Remember to account for proper clearance so stored sheets don't interfere with lighting fixtures or other overhead installations. This approach particularly benefits smaller workshops where every square foot of accessible space counts toward productive work area.

4. Horizontal Shelf Storage Method

Horizontal shelf storage provides easy access to plywood sheets while maintaining their flat orientation, preventing the warping that sometimes occurs with vertical storage. This system resembles oversized bookcase shelving, with wide platforms supported by robust vertical posts anchored to walls or freestanding frames. Each shelf accommodates stacked sheets with sufficient spacing between levels to prevent excessive weight compression on lower materials. You can customize shelf depths to match your most commonly used plywood dimensions, typically ranging from two to four feet deep. The horizontal arrangement allows you to quickly flip through stacked sheets like pages in a book, making material selection effortless. Consider adding front stops to prevent sheets from sliding forward and creating safety hazards. This storage style works exceptionally well when you regularly work with partial sheets or pre-cut plywood pieces.

5. Lean-To Wall Storage Design

The lean-to wall storage design offers the simplest possible plywood organization method, requiring minimal construction skills and materials while delivering effective results. This approach involves creating an angled support frame against a workshop wall where plywood sheets rest at approximately fifteen to twenty degrees from vertical. The slight angle prevents sheets from tipping forward while gravity helps keep them snugly against the wall surface. You'll need only basic two-by-four lumber to construct bottom supports and occasional vertical dividers that separate different material types. This budget-friendly solution works perfectly for temporary storage needs or workshops where permanent installations aren't feasible. The open design allows excellent air circulation around stored materials, reducing moisture accumulation that could cause warping or delamination. Your plywood remains immediately visible and accessible without complicated retrieval mechanisms or heavy lifting.

6. Pipe and Lumber Rack Combination

A pipe and lumber rack combination creates versatile storage that accommodates both sheet goods and dimensional lumber in one cohesive system. This clever design uses sturdy metal pipes or wooden arms extending horizontally from wall-mounted brackets, with longer arms below supporting plywood sheets vertically. The upper sections feature shorter arms perfect for storing two-by-fours, trim pieces, and other lumber that would otherwise clutter your workspace. You can customize arm lengths based on your specific material inventory and available wall space, creating a personalized storage solution. The open design permits easy access from multiple angles, making material selection quick and intuitive even during busy project phases. Installation requires locating wall studs and using appropriately rated hardware to support potentially hundreds of pounds of material. This dual-purpose approach maximizes storage efficiency while maintaining clear organization between different material categories.

7. Mobile A-Frame Storage Stand

A mobile A-frame storage stand combines portability with stability, creating a freestanding plywood holder that moves anywhere your projects demand. This triangular structure features two angled sides meeting at a central peak, with horizontal supports creating storage bays on both faces. The A-frame design provides inherent stability without requiring wall attachment, making it perfect for rental spaces or frequently reconfigured workshops. Heavy-duty wheels on one end allow you to pivot and roll the entire unit like a wheelbarrow, while the opposite end rests firmly on the floor during use. You can construct this storage solution using basic carpentry skills and readily available materials like plywood and dimensional lumber. The double-sided design effectively doubles your storage capacity within the same floor footprint, maximizing space utilization. Your plywood sheets remain protected and organized while maintaining complete workshop flexibility.

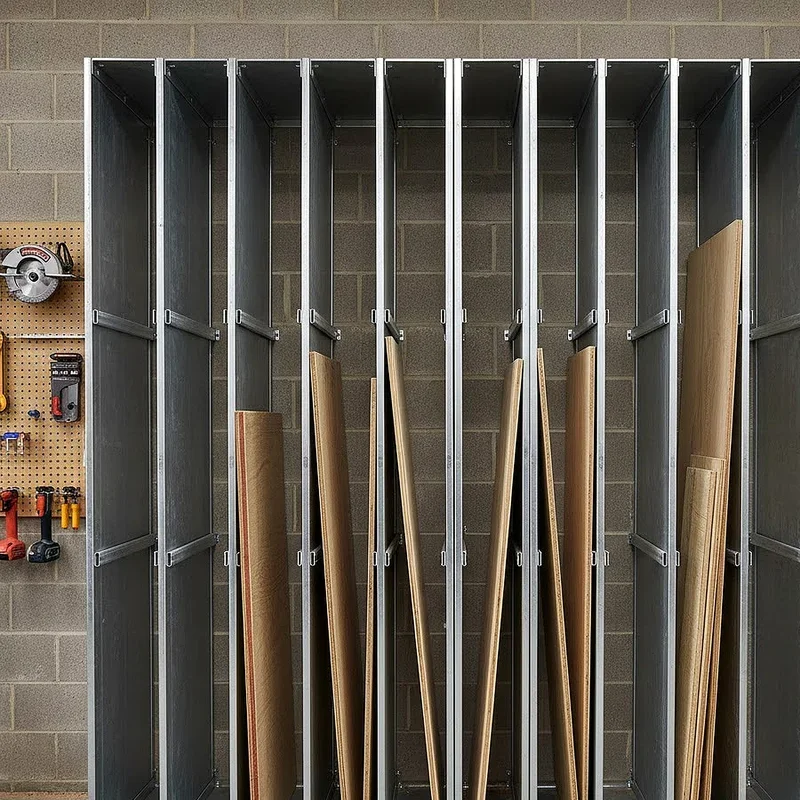

8. Slot-Style Vertical Dividers

Slot-style vertical dividers transform a basic storage frame into an organized filing system for plywood sheets, keeping different materials separated and easily identifiable. This method involves creating multiple vertical slots within a frame structure, similar to how vinyl records stand in a crate. Each slot accommodates one or several sheets depending on your organizational preferences and material inventory size. The dividers prevent sheets from leaning against each other at awkward angles that could cause warping over time. You can label each slot according to plywood type, thickness, or project designation, creating a visual inventory system that saves searching time. Construction requires accurate measurements and consistent spacing to ensure slots remain functional and sheets slide in smoothly. This organizational approach particularly benefits workshops that maintain diverse plywood inventories requiring frequent access and easy differentiation between material grades.

9. Under-Workbench Storage Bins

Under-workbench storage bins capitalize on often-wasted space beneath work surfaces, creating convenient plywood storage that keeps materials hidden yet accessible. This approach involves installing shallow pull-out drawers or rolling bins that slide beneath your primary workbench on tracks or casters. The low-profile design accommodates cut-off pieces and partial sheets that are too valuable to discard but too small for standard vertical storage. You can organize materials by size, type, or current project requirements, keeping frequently used pieces within arm's reach during active work sessions. Consider adding dividers within bins to prevent smaller pieces from shifting and becoming disorganized during drawer movement. The enclosed nature of this storage method protects materials from dust accumulation and incidental workshop debris. Your workspace maintains a clean appearance while maximizing every available cubic inch for productive storage rather than empty dead space.

10. Cantilever Rack System

A cantilever rack system provides professional-grade plywood storage using horizontal arms that extend from a vertical post structure without front column obstruction. This industrial-strength solution allows unimpeded access to stored materials since no vertical supports block the front loading area. The arms adjust vertically on the support columns, letting you customize spacing based on current inventory and accommodate various sheet thicknesses. Heavy-duty construction supports substantial weight loads, making this system suitable for commercial workshops with extensive material inventories. You'll appreciate how quickly you can slide sheets in and out without navigating around support posts or lifting over barriers. Installation requires solid anchoring to workshop floors or walls since the offset weight creates significant leverage forces on mounting points. This storage style delivers maximum accessibility and capacity for serious woodworkers who demand efficiency and organization in high-volume production environments.

11. Pegboard Panel Organization

Pegboard panel organization extends beyond tool storage, offering creative solutions for managing plywood cut-offs and smaller sheet pieces through customizable hook configurations. This versatile system uses standard pegboard mounted to walls with appropriate standoff spacing, allowing hooks and brackets to support lightweight plywood pieces vertically. You can arrange hooks in patterns that accommodate your specific material sizes and shapes, creating a visual inventory that makes piece selection instantaneous. The system excels at storing template materials, jigs, and frequently used cut-off pieces that might otherwise pile up on workbench surfaces. Consider dedicating one pegboard section exclusively to current project materials, keeping everything needed for active work consolidated in one accessible location. The reconfigurable nature of pegboard systems means your storage evolves alongside changing project needs and material inventories. Your smaller plywood pieces finally have a designated home that keeps them organized and prevents valuable scraps from disappearing into workshop chaos.

12. Sliding Storage Cabinet Design

A sliding storage cabinet design conceals plywood sheets behind workshop walls or within dedicated enclosures, protecting materials from dust while maintaining organized accessibility. This system features full-height panels that slide on overhead tracks or bottom rollers, functioning like oversized pocket doors that reveal storage compartments. The enclosed design protects your investment from environmental factors and incidental damage while presenting a clean, professional workshop appearance. You can incorporate this storage into existing wall structures during shop construction or add freestanding cabinet units that serve dual purposes. Interior dividers within cabinets maintain sheet organization and prevent materials from leaning at problematic angles that encourage warping. Consider adding locks if security concerns exist in your workspace, protecting valuable specialty plywoods from unauthorized access. The sliding mechanism operates smoothly with minimal effort, making material retrieval efficient even when storing heavy full-size sheets in cabinet depths.

13. Corner Space Maximization Unit

Corner space maximization units transform often-neglected workshop corners into productive plywood storage areas that efficiently use three-dimensional space. This specialized design features angled supports that fit snugly into corner configurations, with storage faces oriented at forty-five degrees to adjacent walls. The triangular footprint minimizes intrusion into central workshop floor space while providing surprising storage capacity for multiple full-size sheets. You can access stored materials from either adjacent wall side, offering flexibility in workshop layout and traffic flow patterns. Construction requires careful angle measurements to ensure proper fit, but the investment pays dividends in reclaimed usable space. Consider installing this storage type in multiple workshop corners to distribute material inventory and reduce carrying distances during projects. The corner orientation naturally protects stored sheets from incidental contact during normal workshop movement and activity.

14. Adjustable Bracket System

An adjustable bracket system delivers ultimate flexibility in plywood storage by allowing you to reconfigure shelf heights and spacing as your inventory and needs evolve. This modular approach uses vertical standards mounted to walls with movable brackets that lock into place at predetermined intervals. You can quickly adjust storage configurations without tools, adapting to changing material dimensions or inventory levels within minutes. The system accommodates both horizontal and vertical storage orientations depending on bracket styles and spacing choices you implement. This adaptability proves invaluable as your woodworking practice evolves and material preferences shift over time. Heavy-duty commercial standards support substantial weight loads, ensuring safety even when fully loaded with dense hardwood plywood sheets. Your storage grows and changes alongside your workshop development rather than becoming a permanent installation that may eventually limit your options.

15. Portable Dolly Storage Solution

A portable dolly storage solution combines material transport and temporary storage in one mobile unit that adapts to dynamic workshop environments. This wheeled platform features raised edges or side supports that secure plywood sheets during movement while allowing quick loading and unloading. The compact footprint slides easily into narrow storage areas when not actively transporting materials, maximizing floor space efficiency. You can position dollies near cutting stations during active project phases, then roll them against walls when floor space becomes priority. Multiple dollies let you organize materials by project or material type, creating mobile storage clusters that move together through your workflow. The low-profile design requires minimal lifting when loading sheets, reducing physical strain and improving workplace safety. Your plywood becomes truly mobile rather than anchored in fixed storage locations, bringing materials to work areas instead of bringing work to storage.

Conclusion

Organizing your workshop's plywood storage transforms chaos into controlled efficiency, protecting your materials while enhancing productivity. These fifteen storage ideas offer solutions for every workshop size, budget, and workflow preference, from simple lean-to designs to sophisticated cantilever systems. The key lies in selecting approaches that match your specific needs, available space, and typical project requirements. Remember that effective storage isn't just about hiding materials away; it's about creating systems that make your woodworking practice more enjoyable and less frustrating. Start with one storage solution that addresses your most pressing organizational challenge, then expand your system as time and resources permit. Your future self will thank you every time you effortlessly locate the perfect plywood sheet without excavating through unstable stacks or risking material damage.

Read next: 15 Outdoor Firewood Storage Ideas for Neat Stacking

Frequently Asked Questions

Q1: What is the best way to store plywood vertically or horizontally?

A: Vertical storage saves floor space and prevents warping when properly supported with adequate backing.

Q2: How do I prevent plywood from warping in storage?

A: Store sheets flat or vertically supported, maintain consistent humidity, and ensure proper air circulation.

Q3: What spacing should I use between plywood storage dividers?

A: Allow two to four inches between dividers to accommodate multiple sheets while maintaining easy access.

Q4: Can I store plywood outside my workshop?

A: Outdoor storage requires weatherproof covering and elevation to prevent moisture damage and material deterioration.

Q5: How much weight can wall-mounted plywood racks safely hold?

A: Properly installed racks anchored to studs typically support 200-400 pounds depending on bracket quality.