15 Clamp Storage Ideas to Organize Your Workshop

Transform your cluttered workshop with 15 innovative clamp storage ideas. From wall racks to mobile carts, organize every clamp type efficiently.

Ever spent more time hunting for the right clamp than actually using it? If you're nodding your head, you're not alone! A disorganized clamp collection can turn a simple project into a frustrating treasure hunt. Clamps seem to multiply in workshops, sprawling across benches, hiding in corners, and tangling with each other like mischievous metal serpents. But what if your clamps could live in perfect harmony, each one easily accessible when inspiration strikes? Whether you're dealing with a modest collection or enough clamps to build a small city, these 15 storage solutions will transform your workshop from chaotic to calculated. Ready to spend less time searching and more time creating?

1. Wall-Mounted Pipe Rack Systems

Wall-mounted pipe racks transform empty wall space into efficient clamp storage gold. Install horizontal pipes or dowels at varying heights to accommodate different clamp sizes and styles. This system works brilliantly for bar clamps, pipe clamps, and parallel clamps that can hang by their bars. You'll love how easily you can grab exactly what you need without disturbing other clamps. Space pipes strategically to prevent clamps from tangling while maximizing storage density. Consider using galvanized steel pipes for heavy-duty support or wooden dowels for a warmer workshop aesthetic. Mount brackets into wall studs for maximum strength, especially when storing hefty clamps. Add labels above each section to designate specific clamp types. The visual organization makes inventory management simple at a glance. This classic solution has stood the test of time for good reason.

2. Pegboard Organization Solutions

Pegboard systems offer unmatched flexibility for evolving clamp collections. Install heavy-duty pegboard panels and experiment with various hook configurations until you find your perfect setup. The beauty lies in easy reconfiguration as your tool collection grows or changes. Use different hook styles for different clamps: single hooks for C-clamps, double hooks for spring clamps, and specialized holders for unique shapes. Paint pegboard sections in different colors to create visual zones for clamp categories. You can add small shelves or bins to pegboard for storing clamp accessories like pads and jaw covers. The perforated surface accepts countless accessory options beyond basic hooks. Position frequently used clamps at comfortable reaching height while storing specialty clamps higher or lower. This adaptable system grows with your workshop needs. Many woodworkers consider pegboard the Swiss Army knife of workshop organization.

3. French Cleat Storage Systems

French cleat systems bring museum-quality organization to workshop clamp storage. These angled wooden strips create incredibly strong, adjustable mounting points for custom clamp holders. Build specific holders for each clamp type, then simply lift and reposition as needed. The 45-degree angle locks holders securely while allowing instant removal. You'll appreciate the modular nature when reorganizing or adding new clamp types. Create holders from scrap wood, customizing each to perfectly cradle specific clamps. The system handles substantial weight when properly installed into wall studs. Paint or stain cleats to match your workshop aesthetic while improving visibility. Some woodworkers add stops or dividers to prevent clamps from sliding along cleats. This sophisticated solution impresses visitors while providing serious functionality. The initial time investment pays dividends in long-term organization. French cleats elevate clamp storage from purely functional to genuinely elegant.

4. Mobile Clamp Carts on Wheels

Rolling clamp carts bring storage directly to your work area, eliminating countless trips across the workshop. Build or buy carts with multiple storage levels, organizing clamps by size or type on different shelves. Heavy-duty locking casters ensure stability during use while allowing easy movement when needed. You'll wonder how you managed without mobile storage once you experience the convenience. Include vertical dividers to keep bar clamps separated and tangle-free. Add bins or drawers for small spring clamps and accessories. The top surface doubles as temporary workspace or assembly area. Consider carts narrow enough to fit between workbenches and machinery. Some designs incorporate pegboard sides for additional hanging storage. This solution particularly suits larger workshops where projects happen in different zones. Mobile storage adapts to your workflow rather than forcing you to adapt.

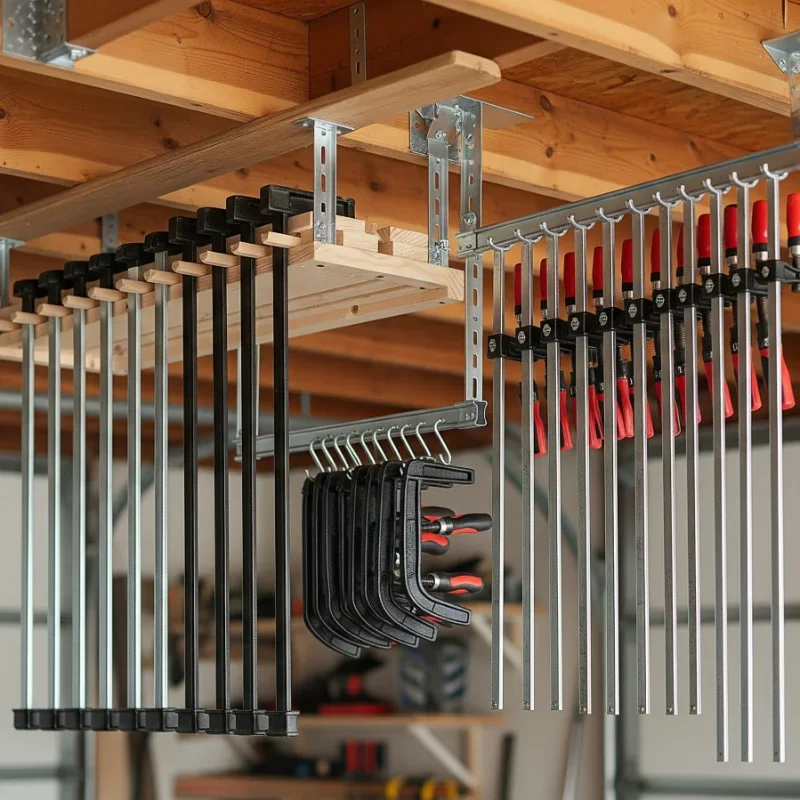

5. Ceiling-Mounted Storage Options

Look up and discover untapped storage potential in your workshop ceiling. Ceiling-mounted systems keep clamps accessible while preserving valuable wall and floor space. Install sturdy hooks, rails, or pulley systems rated for your clamps' combined weight. This overhead approach works especially well for long bar clamps and pipe clamps. You'll maximize vertical space in workshops with limited square footage. Create zones for different clamp lengths to prevent interference when retrieving specific sizes. Some woodworkers use retractable cord systems that lower clamps to working height. Ensure adequate clearance below storage to avoid head bumps. Paint ceiling storage components bright colors for easy visibility and safety. This solution keeps clamps dust-free compared to lower storage options. Consider combining ceiling storage with wall solutions for comprehensive organization. Smart ceiling utilization can double your effective storage capacity.

6. Dedicated Clamp Cabinets

Purpose-built clamp cabinets provide dust-free storage with a professional appearance. Design cabinets with adjustable shelves and specialized compartments for different clamp types and sizes. Doors protect clamps from workshop dust while maintaining a clean visual aesthetic. You can incorporate pull-out drawers for smaller clamps and sliding trays for easy access. Build cabinets tall and narrow to maximize storage while minimizing floor footprint. Include interior lighting for better visibility in deep cabinets. Some designs feature glass doors for quick visual inventory without opening. Add soft-close hinges to prevent slamming and potential clamp damage. Label shelves and compartments for consistent organization habits. This enclosed storage particularly benefits workshops doing finishing work where dust control matters. Custom cabinets can match existing workshop furniture for cohesive design. The investment in quality cabinetry pays off through years of organized efficiency.

7. Under-Bench Sliding Drawers

Transform wasted under-bench space into premium clamp storage with sliding drawer systems. Heavy-duty drawer slides support substantial weight while providing full extension for complete access. Design drawers with dividers creating specific homes for each clamp style. You'll appreciate having clamps at waist height without bending or stretching. Shallow drawers work perfectly for C-clamps and spring clamps, while deeper units accommodate bar clamps laid flat. Install soft-close mechanisms to prevent jarring impacts that could damage precision clamps. Consider clear drawer fronts or labels for quick identification without opening. The enclosed design protects clamps from dust and debris. Some woodworkers create tiered inserts maximizing vertical space within drawers. This hidden storage maintains clean workshop sight lines while keeping tools instantly accessible. Under-bench drawers utilize every cubic inch of available space efficiently. The convenience factor alone justifies the installation effort.

8. Magnetic Strip Storage

Powerful magnetic strips offer instant grab-and-go storage for metal clamps. Mount rare-earth magnetic strips on walls, inside cabinets, or along workbench edges for versatile placement options. This solution excels for smaller clamps like spring clamps, C-clamps, and toggle clamps. You'll love the satisfying snap as clamps lock into place. No hooks or holders needed means zero installation beyond mounting the strips themselves. Arrange clamps by size along strips for visual organization. The open display makes selecting the right clamp instantaneous. Consider mounting strips at various angles for different viewing perspectives. Some strips include protective rubber coating preventing clamp scratches. This method keeps frequently used clamps within arm's reach during projects. Combine magnetic storage with other systems for comprehensive organization. The simplicity and effectiveness of magnetic storage surprises many first-time users.

9. PVC Pipe Organizers

Repurpose PVC pipes into custom clamp organizers that are both affordable and effective. Cut pipes to length and mount horizontally or vertically to create perfect clamp cubbies. Large diameter pipes accommodate bar clamp heads while smaller pipes organize C-clamps beautifully. You can heat and reshape PVC for custom configurations matching your specific clamps. Connect multiple pipes with fittings to build elaborate storage matrices. The smooth interior prevents clamp damage while allowing easy insertion and removal. Paint pipes different colors for visual categorization systems. Mount pipes at angles to display clamps for easy selection. This budget-friendly solution costs fraction of commercial storage systems. Add end caps to prevent clamps from sliding through. The lightweight material makes reconfiguration simple as needs change. PVC's durability ensures years of reliable service in demanding workshop environments.

10. Repurposed Pallet Racks

Transform discarded pallets into rustic yet functional clamp storage with minimal investment. The existing slat spacing often perfectly accommodates various clamp sizes without modification. Mount pallets vertically on walls or stand them freely with simple base supports. You'll appreciate the instant organization without complex construction. Sand rough edges and apply finish for splinter-free handling. The industrial aesthetic appeals to many workshop environments. Reinforce pallets with additional bracing for heavier clamp collections. Paint or stain pallets to match your workshop decor while adding protection. Some woodworkers attach smaller boards creating custom spacing for specific clamps. This eco-friendly solution diverts waste while solving storage challenges. Combine multiple pallets for expanded storage walls. The character of weathered wood adds visual interest beyond mere function. Free materials make this option perfect for budget-conscious organizers.

11. Custom Wood Rack Designs

Building custom wooden racks allows perfect tailoring to your specific clamp collection. Design racks with angled supports, notches, and cradles that match your exact clamp profiles. Use quality hardwood for durability and workshop aesthetics that improve with age. You control every dimension ensuring optimal fit and accessibility. Incorporate different storage methods within single rack units for versatility. Add decorative elements like routed edges or carved details for personalized touch. The building process itself provides satisfying workshop project between larger endeavors. Create modular sections allowing future expansion as collections grow. Some designs include integrated measuring marks for quick clamp size reference. This hands-on approach results in storage perfectly matching your workflow. Consider incorporating LED strip lighting for enhanced visibility. Custom racks become workshop fixtures you'll appreciate for decades. The pride of building your own storage adds intangible value.

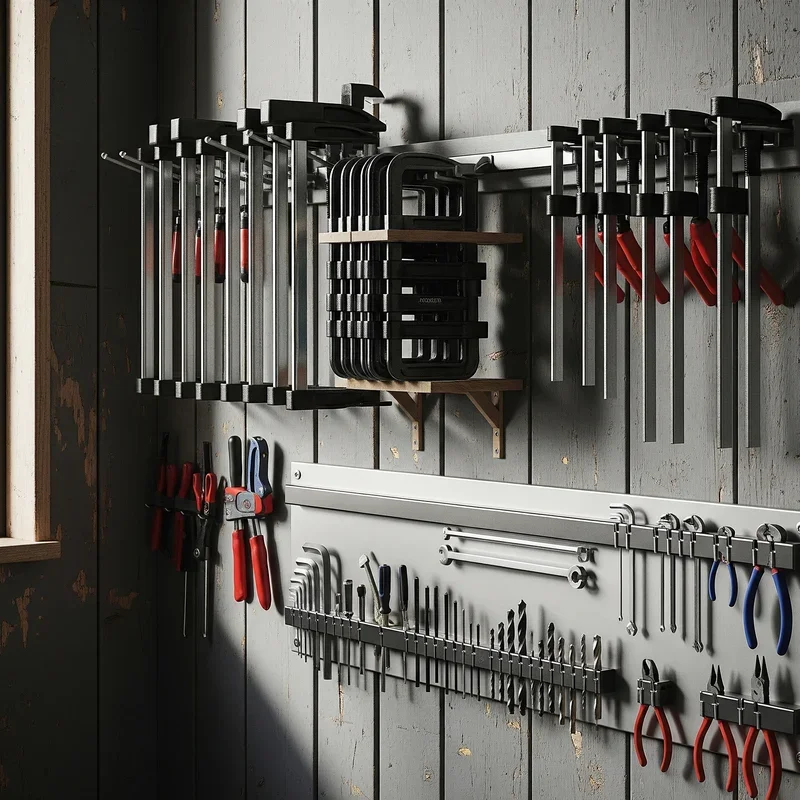

12. Tool Wall Grid Systems

Modern grid wall systems offer industrial-strength organization with endless configuration possibilities. These heavy-duty wire or steel grids accept numerous accessory types for customized clamp storage. Install grids covering entire walls or smaller sections based on space availability. You'll find accessories specifically designed for every clamp type imaginable. The open grid structure provides excellent visibility and ventilation. Reposition hooks and holders instantly without tools as needs evolve. Grid systems handle substantial weight when properly anchored to walls. The modular nature allows starting small and expanding over time. Powder-coated finishes resist rust and wear in humid workshops. Some grids include integrated shelving for mixed storage needs. This commercial-grade solution brings professional organization to home workshops. The initial investment provides lifetime durability and flexibility. Many consider grid systems the ultimate workshop organization tool.

13. Rotating Clamp Towers

Rotating storage towers maximize capacity while maintaining easy access to every clamp. Build or purchase carousel-style units that spin smoothly on bearing systems. Design multiple levels with arms or shelves radiating from central posts. You can access any clamp with simple rotation rather than walking around storage. This compact footprint suits workshops where floor space commands premium value. Include different arm configurations for various clamp types on each level. The vertical design utilizes height efficiently while keeping everything reachable. Some towers feature locking mechanisms preventing unwanted rotation during clamp removal. Add labels or color coding to carousel sections for quick identification. This dynamic storage solution adds kinetic interest to static workshops. Consider motorized rotation for ultimate convenience in large collections. The space efficiency of rotating storage often surprises workshop visitors.

14. Stackable Bin Solutions

Stackable bins provide flexible, scalable storage perfect for growing clamp collections. Choose heavy-duty bins sized appropriately for different clamp categories. Clear bins offer instant visual inventory while colored options enable category coding. You'll appreciate the modular nature allowing easy reconfiguration as needs change. Stack bins on shelving units or directly on floors with proper support. Include labels on bin fronts for consistent organization systems. The contained storage protects clamps from dust and workshop debris. Some bins feature hinged lids for top access without unstacking. Divided bins work excellently for organizing smaller clamps by size. This portable solution allows moving entire clamp categories to job sites. Nest empty bins when not needed to save space. The affordability enables starting small and expanding gradually. Many woodworkers combine bins with other storage methods for complete systems.

15. Hybrid Storage Combinations

Why choose one storage method when combining systems creates ultimate organization? Integrate wall racks with mobile carts, pegboard with magnetic strips, creating comprehensive storage ecosystems. This approach lets each system handle what it does best. You'll develop workflows that feel natural and efficient. Position frequently used clamps on pegboard while storing specialty clamps in cabinets. Use ceiling storage for oversized clamps while keeping daily drivers on mobile carts. The variety prevents any single system from becoming overloaded. Design transition zones where systems meet for smooth organization flow. Some workshops dedicate different walls to different storage philosophies. This eclectic approach accommodates diverse clamp types and working styles. Evolution becomes simple by adding new systems without disrupting existing organization. The flexibility of hybrid systems adapts to changing workshop dynamics. Most experienced woodworkers eventually adopt multi-system approaches.

Conclusion

Organizing your clamp collection transforms workshop efficiency and enjoyment. Choose storage solutions matching your space, budget, and working style. Start with one system and expand gradually as you discover what works best. Remember that the best organization system is one you'll actually maintain. Your future self will thank you every time you reach for exactly the right clamp without searching.

Read next: 15 Apartment Storage Ideas for Every Room

Frequently Asked Questions

Q1: What's the best storage method for a small clamp collection?

A1: Pegboard systems offer maximum flexibility and easy expansion for growing collections efficiently.

Q2: How do I prevent rust on stored clamps?

A2: Use climate-controlled cabinets or add silica gel packets to enclosed storage areas.

Q3: Should I organize clamps by size or type?

A3: Organize by type first, then size within each category for intuitive access.

Q4: What weight capacity do I need for clamp storage?

A4: Calculate total clamp weight and add 50% safety margin for secure mounting.

Q5: Can I build effective clamp storage from scrap materials?

A5: Absolutely! Scrap wood, PVC, and pallets create functional storage with minimal investment.